Learning how to repair small engines has many benefits.

You probably care a lot about the condition of the engine in your car or truck, as you should. But you also should be concerned with the engine in your lawn mower. You should care about the condition of the engine in your weed-whacker or your chainsaw. And if you live somewhere where you need them, you should definitely care about the engines in your emergency generator and snowblower.

Someone has to make sure these small engines keep running, of course. Someone has to repair the snow blowers we rely on in the wintertime. And while the engines may not be as large as the engines in an automobile, they are every bit as important and just as complex.

If you would like to learn how to repair small engines, there are several directions you could take. You can, of course, try to teach yourself. As you probably predicted, this can be exceptionally difficult. Vocational and technical schools offer certifications and degrees in small engine repair, but these programs can be extremely challenging. The fact that small engines is not a subject covered in school just makes it worse.

Why Distance Learning Can Help

There is an option other than teaching yourself or heading right to a trade school. Through Stratford’s distance learning class, you can learn at your own pace and be well-prepared for continuing education or certification programs.

What Will You Learn?

When learning how to repair small engines, here are just a few things that you should find in your coursework:

Tools and Safety

- It’s always important to start out with an understanding of how to be safe while working on anything. This portion of the course is designed to make sure you know how to use the tools and how to prevent injury.

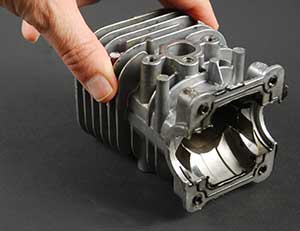

The Basics of Small Engine Design

- This is just a basic overlook at how a small engine works and what the parts are.

Fasteners, Sealants, and Gaskets

- These parts are important to an engine, preventing loss of efficiency. Learning about them is essential to mastering engine repair and upkeep.

Two-Cycle and Four-Cycle engines

- Learning the difference in construction between the two common types of small engines is essential. Any course that doesn’t teach the difference is doing you a disservice.

Ignition, Lubrication, and Cooling Systems

- The ignition system in a small engine provides the initial spark to provide combustion.

- Lubrication systems ensure that metal is protected and prevents undue damage to moving parts.

- Cooling ensures that the engine doesn’t overheat and cause damage to the device.

Electric System Servicing

- The electric system in small engines is mostly there to control engine speed and to provide the initial ignition for the engine. It is still a very important part of the engine, though.

Cylinder, Crankshaft, and Piston Service

- These three pieces are what creates the ‘drive’ of the engine. Understanding how they work together and how to repair them is an essential part of engine repair.

This list is by no means all-inclusive. However, if you are looking to learn how to repair engines, these are just a few essential aspects you must understand.

Interested in learning more about a career in small engine repair? Download our guide to Small Engine Repair Training below!

Excellent Small Engine Repair Courses

Whether you’re ready to get started or you need more information about our courses, we’re here to help.